The Unseen Accumulation: Our Soft Plastic Predicament

For years, the flimsy plastic bag has been a silent accumulator, multiplying in drawers, under sinks, and in forgotten corners of our homes. Despite our best efforts—reusable bags, conscious consumption—soft plastics like grocery bags, bubble wrap, and cling film continue to pile up. The dilemma? Most municipal recycling facilities simply can’t process them, leaving us with few options beyond landfill, or worse, environmental pollution.

This pervasive problem, which sees countless plastic fragments ending up in our oceans, rivers, and even tangled in trees, highlights an urgent need for innovative solutions. Enter Clear Drop, a company stepping up to address this very challenge with a novel household device.

Introducing the Clear Drop Soft Plastic Compactor (CPC)

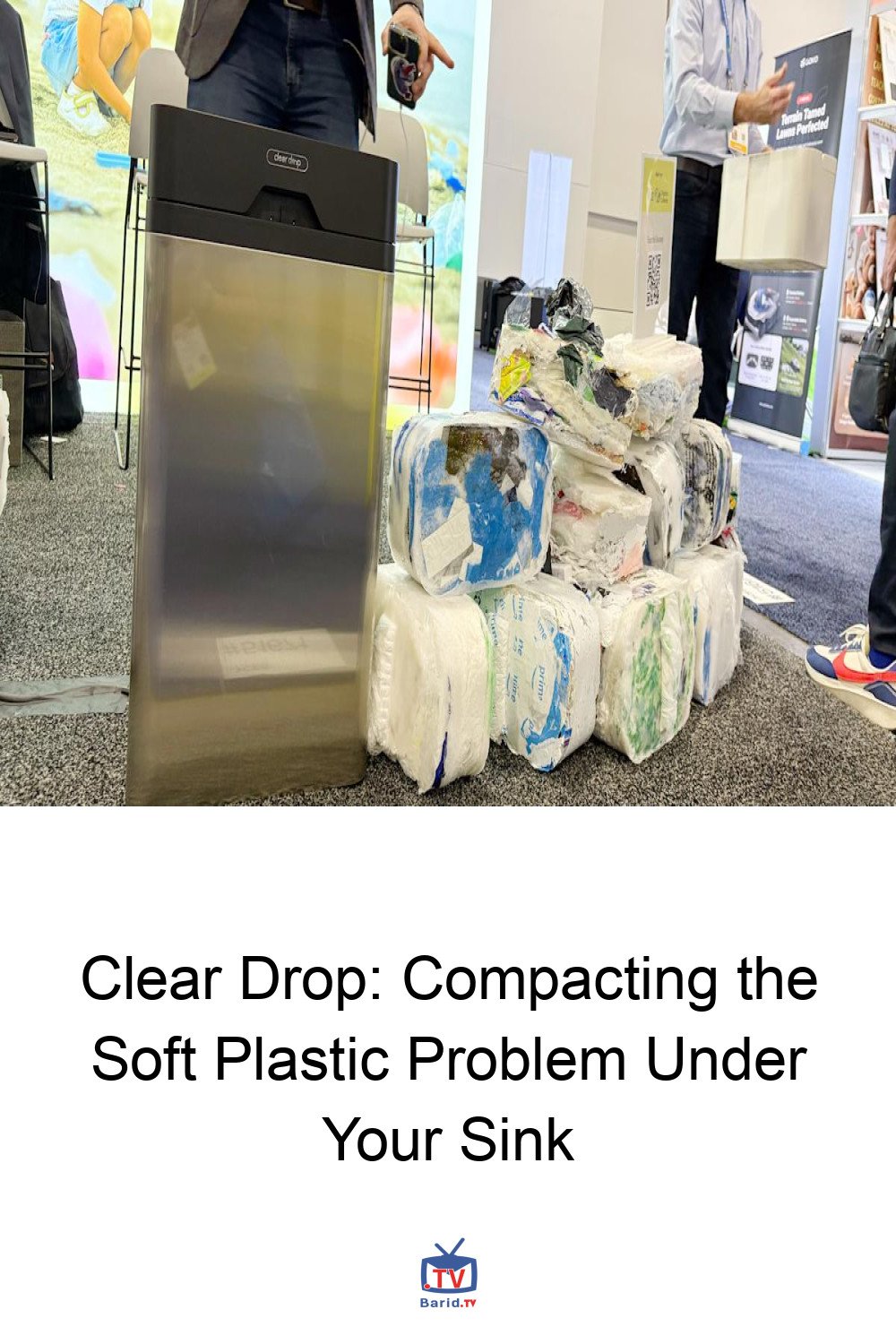

Unveiled at CES, the Clear Drop Soft Plastic Compactor (CPC) presents a compelling pre-recycling solution for the home. This ingenious machine transforms hundreds of disparate soft plastic items into a single, dense brick, significantly easing transport and preparing them for specialized recycling facilities.

How It Works: From Fluff to Form

The CPC boasts an impressive compatibility, handling approximately 95 percent of common soft plastics. This includes everything from shopping bags and Ziploc bags to package wrap and cling film. The process is straightforward: plastics are fed into the device, where they are compressed and heated. The result is a compact, solid brick measuring eight by twelve by four inches.

Matt Daly, Clear Drop’s head of product, clarified the few exceptions: ping pong balls, IV bags, and camera film are among the items the compactor cannot process. During demonstrations, the machine efficiently consumed plastic bags, and while the unit at the show wasn’t set to heat, Clear Drop representatives assured minimal plastic odor and confirmed rigorous safety tests to prevent harmful emissions.

The Journey of a Plastic Brick: From Home to Recycling

For the average household, Clear Drop estimates it takes about a month to produce one brick, equivalent to roughly a 30-gallon trash bag full of soft plastics. Once formed, these bricks can be shipped to one of Clear Drop’s partner facilities, with pre-paid USPS shipping envelopes conveniently included. The company collaborates with multiple US-based recycling centers and conducts regular audits to ensure the bricks are genuinely recycled.

While the inability to simply toss these bricks into curbside recycling bins might seem like a drawback, Daly confirmed that Clear Drop is actively working to expand its network of recycling partners. The ultimate vision is to integrate with municipal recycling infrastructures, making the process even more seamless for consumers. Currently, the shipping aspect, though necessary, does introduce a layer of logistical and environmental consideration.

Investment in a Greener Future

The Clear Drop CPC, priced at $1,400 (payable over two years), represents a significant investment for a household appliance. However, for those deeply concerned about their environmental footprint and the fate of their soft plastic waste, it offers a tangible, proactive solution.

In a world grappling with escalating plastic pollution, Clear Drop offers a beacon of hope. While not a perfect panacea, it stands out as one of the most effective household-level interventions available today, ensuring that countless plastic bags are diverted from landfills and fragile ecosystems, safeguarding marine life and promoting a cleaner planet.

For more details, visit our website.

Source: Link