For years, the dream of owning a truly powerful CNC mill at an accessible price point remained just that – a dream. High-performance machining was often synonymous with industrial-grade budgets. Enter the Shariff DMC2 Mini, a desktop marvel from a Canadian innovator that promises to shatter these preconceptions. But this isn’t your average plug-and-play gadget; it’s a beast that demands respect, and perhaps, a significant investment of your own elbow grease.

Unleashing Raw Power on Your Desktop

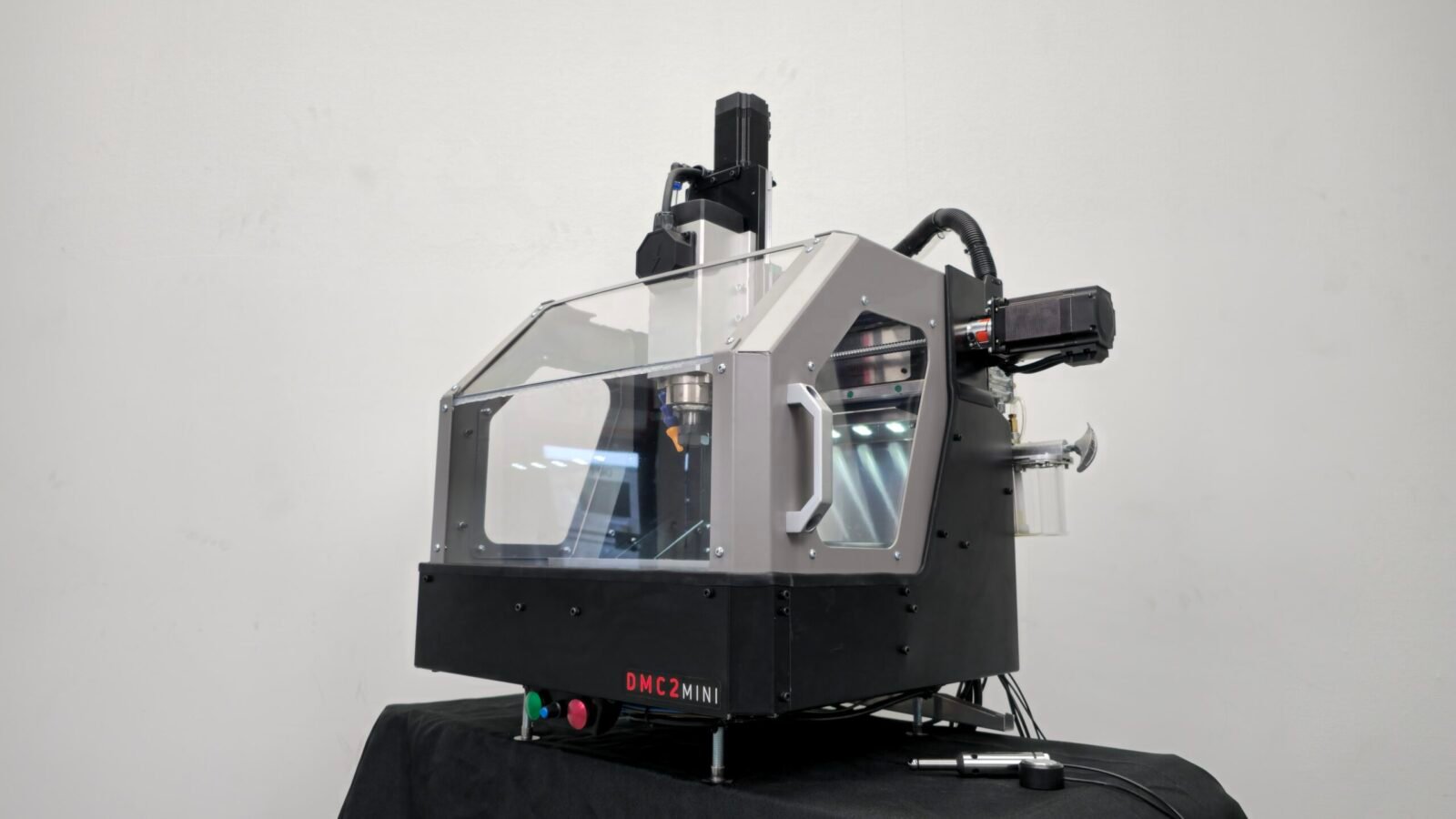

Crafted by Shariff, a burgeoning company based in Ontario, Canada, the DMC2 Mini is their second iteration, and it’s clear they’ve learned a lot. Boasting a generous 12″×7″×5½” work area and an impressive 6½ inches of internal Z height – ample space for a robust vise – this machine is designed for serious work. Its specifications read like a wish list for any aspiring or professional machinist.

Phenomenal Specifications

Under the hood, the DMC2 Mini is anything but mini in performance. Each axis is driven by a formidable 36V, closed-loop NEMA 23 motor, ensuring precision and power. The heart of its cutting prowess is a ferocious 2.2kW 24,000 RPM spindle, capable of tearing through materials with remarkable speed. Complementing this power are essential industrial features: a flood cooling system to manage heat and a dedicated lubrication system for its linear rails and ball screws, promising longevity and consistent performance. We witnessed it carve through a chunk of aluminum with startling ease, and Shariff confidently states its capability across plastics, tool steels, titanium, and more. All this, at a price point that genuinely disrupts the market for desktop-scale CNC mills.

The DIY Journey: Building a Beast from the Ground Up

Herein lies the ‘catch’ – or rather, the unique proposition – of the DMC2 Mini. While an assembled unit is available, the $2,700 DIY kit offers a nearly $2,000 saving, a compelling draw for the true maker. This significant price difference isn’t merely a discount; it’s an accurate reflection of the profound commitment required to bring this machine to life. Assembling the DMC2 Mini is less like putting together a model and more akin to constructing a complex piece of industrial machinery from its fundamental components.

A Hands-On Odyssey

Our experience building the kit, with the invaluable assistance of Make: alum Marty Marfin, was an education in itself. Neither of us had tackled a full CNC mill build before, yet the process, though extensive, was profoundly rewarding. If some desktop CNCs aim for the polished, user-friendly experience of an Apple product, the DMC2 Mini embraces the spirit of an overclocked Linux box – powerful, customizable, and unabashedly technical. Wires snake, tubes connect, and the internal workings are proudly on display. While cable management became a test of patience, it’s a small price to pay for the intimate understanding gained from connecting every single part.

Navigating the Build: Challenges and Triumphs

The kit arrives in six substantial boxes, with no pre-assembled components. Every one of the 200+ nuts and bolts, every drilled and tapped hole in the square steel tubes, demands your personal attention. The 270+ pages of instructions, while comprehensive with multiple photos and renders, are a testament to the build’s complexity. Yet, surprisingly, mistakes were few, a credit to the documentation. For those who relish the meditative process of assembly, much of the build is straightforward, if occasionally tedious. It took us over 40 hours of collaborative effort – a long, but ultimately fulfilling, journey.

Beyond Assembly: The Deeper Understanding

Building the DMC2 Mini isn’t just about saving money; it’s an unparalleled educational experience. It demystifies an incredibly complex device, breaking it down into comprehensible parts. This hands-on immersion provides a deep understanding of how such machines function, raising the bar for future projects and empowering the builder with newfound confidence and capability.

Minor Quirks, Major Learning

No complex build is without its peculiarities. Sealing parts for the cooling system with silicone proved to be a messy, less glamorous step than the mechanical assembly, but essential nonetheless. We noted the manual’s warning about the ‘skinny, spindly legs,’ which, while holding up, required careful handling. Some engineering assumptions were challenged: drilling a hole in the precision probe to bypass batteries, and using M4 screws for inductive sensors that were larger than their mounting holes, gave the build a ‘renegade’ rather than ‘polished’ feel. These aren’t standard, but they work, and they contribute to the machine’s unique character. Similarly, some wiring instructions relied on partial descriptions, adding a layer of interpretation to the process.

Conclusion

The Shariff DMC2 Mini is not for the faint of heart, nor for those seeking instant gratification. It is a powerful, uncompromising desktop CNC mill designed for the dedicated maker, the curious engineer, and anyone willing to invest their time and effort into understanding and building their tools. What you get in return is not just a machine, but an education, a sense of profound accomplishment, and a truly formidable tool capable of tackling projects once thought impossible on a desktop budget. It’s a testament to what can be achieved when raw power meets DIY spirit.

For more details, visit our website.

Source: Link

Leave a comment