Tired of the Sandpaper Shuffle? Organize Your Workshop with the Ultimate Grit Stash!

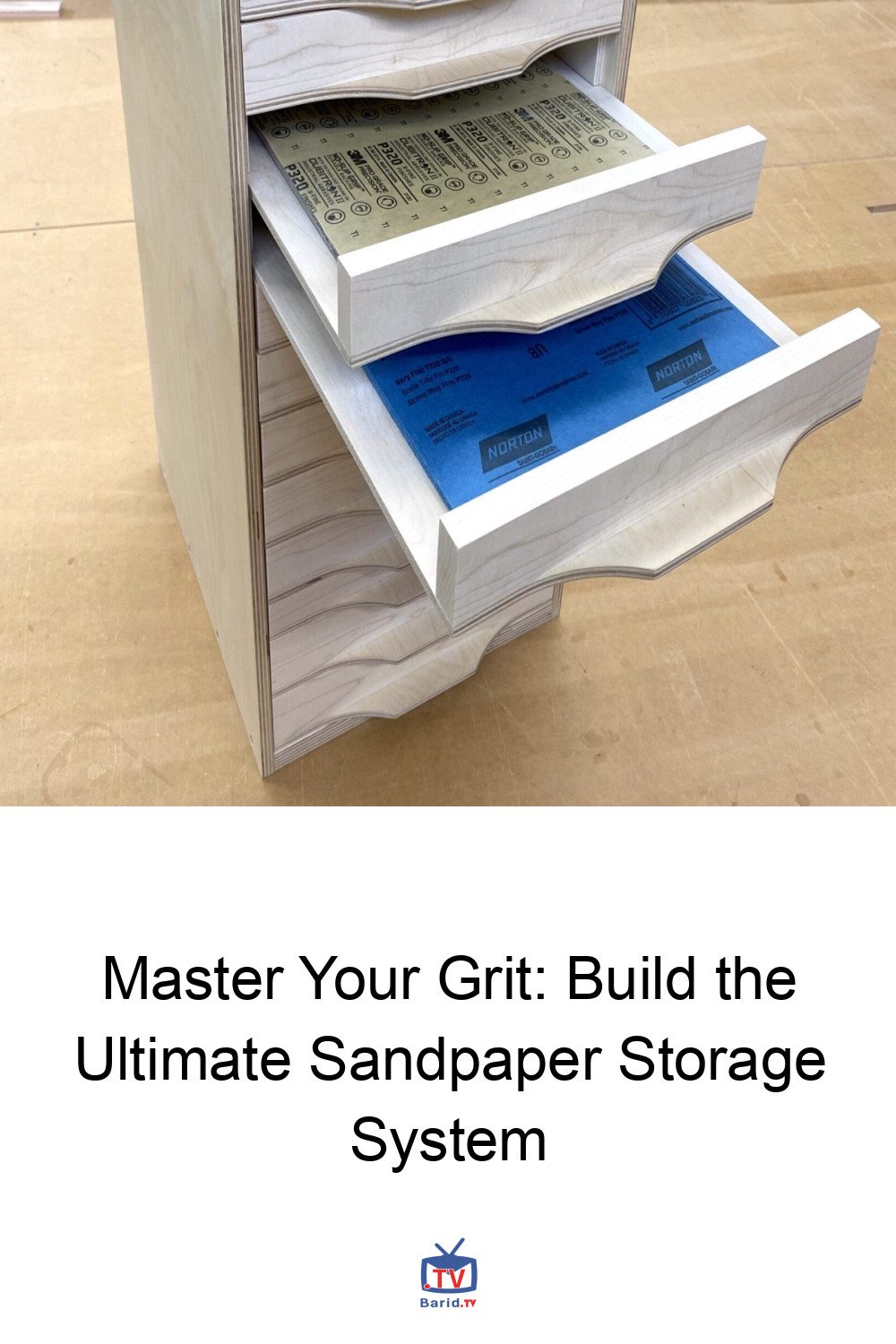

Every dedicated maker knows the struggle: a drawer overflowing with random sandpaper sheets, mysterious partial pieces, and the constant hunt for the right grit. It’s a frustrating inefficiency that can derail even the most focused project. But what if you could banish the chaos and bring professional-level organization to your abrasive arsenal? Enter the Grit Stash: a custom-built sandpaper flat file designed to streamline your workflow and keep every grit precisely where it belongs.

The Problem with Unruly Abrasives

Loose sheets rubbing together lose their effectiveness, cardboard sleeves hide their contents, and those unmarked scraps become a guessing game. This disarray isn’t just annoying; it wastes time and money. Imagine a system where every grit, from coarse 60 to ultra-fine 2000, has its own dedicated home, easily accessible and perfectly preserved.

Introducing the Grit Stash: Your Workshop’s New Best Friend

This ingenious sandpaper flat file, featured in Make: Vol. 78, is more than just a storage box – it’s a productivity enhancer. Designed for ease of use and maximum organization, it offers:

- Dedicated Grit Drawers: Ample space for all your essential grits, from 60 to 400, plus specialized drawers for super high grits (1000-2000).

- Accessory Storage: A dedicated drawer for sanding sticks, blocks, and other essential tools.

- Re-Use & Recycle: A specific spot for lightly used pieces, ensuring you get every last bit of life out of your abrasives.

- Hidden Efficiency: A narrow, secret drawer that doubles as a straightedge tearing board, allowing you to quickly and accurately create half sheets on demand.

This project is an accessible and rewarding build, taking just 1-2 days with an estimated cost of $100. Whether for your personal workshop, a community makerspace, or as a thoughtful gift for a fellow craftsman working with wood, fiberglass, resin, or other fabrication materials, the Grit Stash is an investment in efficiency and order.

Crafting Your Grit Stash: Materials and Methods

Building this flat file involves precise cuts and thoughtful assembly. The original design utilizes maple wood, dimensioned to 5/8″ thick for the drawer fronts using a jointer and planer. However, accessibility to such tools isn’t a barrier to entry.

Wood Selection: Precision vs. Practicality

If you don’t have access to a jointer and planer, you can easily adapt the design to work with readily available off-the-shelf ¾” wood. Simply select the straightest pieces possible and rip them to size on a table saw. To accommodate the slightly thicker material, you’ll make a few minor adjustments:

- Increase carcass depth by 1/8″ (to 13⅛″).

- Widen the front rabbet from 21/32″ to ¾″.

- Deepen the drawer bottoms by 1/8″ (to 13⅝″).

A SketchUp drawing is available for download, offering a flexible blueprint that can be modified to suit your specific needs and material choices. Photography by Len Cullum showcases the professional finish achievable.

Demystifying Woodworking Joints: Dados and Rabbets

This project makes excellent use of fundamental woodworking joints. Understanding these terms is key to a successful build:

- Kerf: The space removed by a saw blade during a cut, essentially the sawdust.

- Dado: A wide, flat-bottomed groove cut across the grain of a board, often used for shelves or drawer bottoms.

- Groove: Similar to a dado, but cut along the grain. While technically distinct, these terms are frequently used interchangeably in practice.

- Rabbet: A two-sided groove cut along the edge of a board, creating a step or L-shaped profile. Perfect for joining pieces or creating recesses.

Ready to Build? Your Steps to Sandpaper Serenity:

The construction process is straightforward, broken down into manageable steps:

- Cut the Carcass Pieces

- Lay Out the Drawer Dados

- Cut the Dados

- Cut the Rabbets

- Build the Carcass

- Cut the Drawer Bottoms

By following these steps, you’ll soon have a workshop that’s not just organized, but a joy to work in. Say goodbye to the grit guessing game and hello to efficiency!

For more details, visit our website.

Source: Link

Leave a comment